SERVO VOLTAGE STABILIZER

Voltage variation is the common phenomenon across the world , Due to changing the load pattern of distribution lines .Gingerly in day time voltage is low and high during night hours it occurs only an on due to long distribution line ,ground falts,unit located towards end of a long supply line ,high voltage surges might be generated by disconnection of large load, increase voltage in generation plant and unit located to close to generation point. One of the main uses in servo voltage stabilizer in un-balanced type load-phase to phase unbalancing in voltage is generly observed where multiple consumer draw power in a common line

This higher current affects the electrical motors (particularly smaller capacity motors upto 7.5 H.P.) in three ways:

1. Higher current produces higher losses in electrical motors which causes premature failure of winding.

2. These higher losses of electric motors also increase the losses of cables, switches, transformers & other associated equipments.

3. For smooth continuous operation of motors, over load relays are usually set at 20% higher setting.

With the installation of the Servo Controlled Voltage Stabilizer and maintaining 390/400 volts, the motor will operate smoothly drawing 15 - 20% lesser current

The table below compares the behavior of 5 H.P. motor at different voltage:

| Input Voltage | Current | KVA | PF |

| 400 | 7.5 A | 5.2 | 0.8 |

| 425 | 11% More | 18% More | 0.7 |

| 435 | 19% More | 28% More | 0.61 |

| 445 | 26% More | 38% More | 0.57 |

To work effectively we need a constant power ,most of the electrical equipment require constant voltage supply to run efficiently, electrical motor draw hi current at high\low voltage

Loss Comparison of Marathon Make Regulator & Conventional makeS

| Capacity | Marathon make Roller type regulator losses | Conventional make Carbon brush type Dimmerstat losses |

| 60 A | 575 W | 1050 W |

| 75 A | 730 W | 2055 W |

| 100 A | 900 W | 3105 W |

Table below gives approximate quantitative advantages of automatic voltage controller at various fluctuation levels:

| Input Voltage Variation | % Reduction in Breakdown Possible | Approx. Power Saving Possible | ||

| 380-400 volts | Nil | Nil | Nil | Nil & Servo Stabilizer Required |

| 380-420 volts | 5% | 10% | 3% | 5% |

| 380-440 volts | 10% | 20% | 5% | 10% |

| 360-460 volts | 40% | 40% | 7% | 20% |

| 360-480 volts | 60% | 60% | 10% | 30% |

| 340-500 volts | 80% | 80% | 15% | 37% |

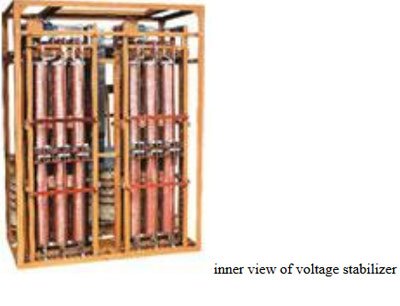

Description of Servo Controlled AVC:

Marathon Servo Stabilizer is manufactured as per IS : 9815 and primarily consists of the following:

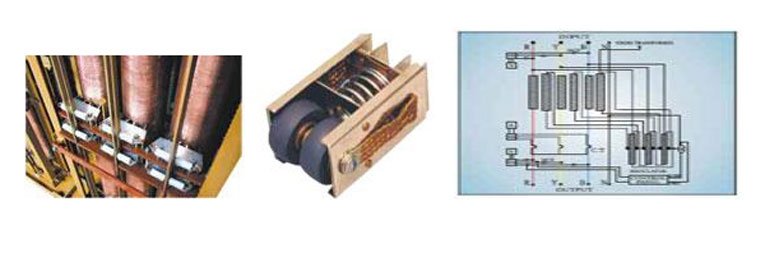

1. Liner Plus / Minus Type Vertical Rolling Contact Voltage Regulator:

In our regulator we are using heavy section of electrolytic grade rectangular copper strip instead of copper wire to minimize the losses & increase the efficiency of equipment. We are also using self lubricating Carbon Roller Assemblies instead of ordinary Carbon Brushes which offers more reliability and trouble free performance of the equipment.

AVC's Application

- Cement Plant

- Paper Mills

- Footwear & Leather Units

- Flour Mills

- Tube Mills

- Distilleries & Beverage

- Engineering Units

- Rice Shellers

- Hospitals

- Pharmaceutical Units

- Footwear & Leather Units

- Rubber Industries

- Nursing Home

- Cold Storage

- Tea Estates

- Clubs

- Rolling Mills

- Food Processing Units

- High Rise Buildings

- Textiles Mills

- Oil and Vanaspati Plant

- Mall & Multiplex

Comparison of Automatic Voltage Controller

| Linear Regulator with rolling contact carbon roller assembly | Dimmer Regulator sliding contact carbon brush assembly |

| Power Consumption is below 0.5 to 1.5% depending upon the input voltage range. | Suitable for 100% duty cycle |

| Life at full load is more than 15 years | Five years guarantee |

| Power Consumption is above 2 to 7% depending upon the input voltage range. | Suitable for less than 50% duty cycle |

| Life at full load is less than 3 years | One Year Guarantee |

2. Double Wound Buck / Boost Type Series Transformers:

In our Buck / Boost transformer we are using CRGO lamination to minimize iron losses and coils of uck/Boost transformer are wound with heavy section of multi strips electrolytic copper to minimize copper losses for getting better efficiency of the equipment.

3. Electronic Control Circuit and Meter Panel:

Marathon Automatic Voltage Controller consists of very simple electronic control circuit for monitoring and controlling voltage, repair & maintenance of which is very easy.

The regulator and Buck / Boost transformer are oil cooled, housed in same or separate sheet steel tanks. Radiators are provided for effective cooling. The coils of voltage regulator & Buck / Boost Transformers are vacuum impregnated and oven dried as per IS.

Temperature Rise:

It is designed for 30-35 degree C above ambient. Suitable for any kind of ambient temperature conditions.

Core:

Core is constructed from Low Loss of CRGO M-4 Grade confirming to latest standards & is fitted & clamped with special built in-house frames to reduce the magnetic noise & to make the structure rigid & robust.

Windings:

Use paper covered electrolytic grade copper strip for winding. Cooling ducts are provided to keep the hot spot temperature as low as possible.

Tanks & Paint:

Tanks are made of M.S. Sheets with adequate bracing & stiffeners are given a coat of Epoxy Primer & Epoxy paint for better life. Both light grey & Siemens grey (RAL 7032) are available in colour.

CUSTOMER CARE

If you have an emergency need, simply call our 24 x7 hour helpline

Copyright © 2024 All Rights Reserved.