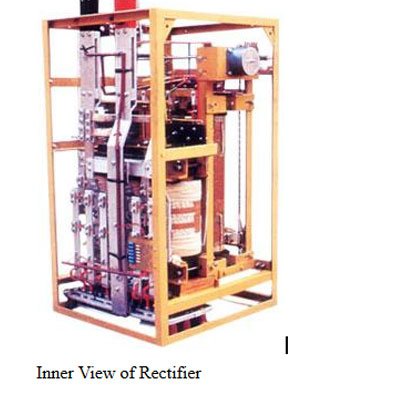

Rectifier

ELECTROPLATING, CLEANING, ETCHING, STRIPPING, BARRELLING, ANODISING, HYDROGENATION AND OTHER ELECTROCHEMICAL PROCESS

. Rectifier is an economical and most efficient method of obtaining DC from AC supply. marathon manufactures a wide range of rectifiers covering 0-500 Volts and upto 15000 Amps. capacity suitable for Electroplating, Anodising, Hydrogenation and many other Electrochemical processes. The entire manufacturing process is under one roof ensuring 100% quality product Brief Specifications

- Input Voltage : 380-440 Volts, 3-phase 50hz. AC supply

- Output Voltage : Fixed Rated maximum DC voltage or variable from zero to maximum rated voltage.

- Output Current : Rated maximum DC current

- Temperature Rise : Less then 350 C above ambient at the top of the oil.

- Efficiency : 12V Rect - 82% , 24V Rect - 90%

- 100V Rect - 94%, 200V Rect - 96%

- More than 250V Rect - More than 97%

- Ripple Content : Less than 5%

- Insulation : 'A' class for oil cooled.

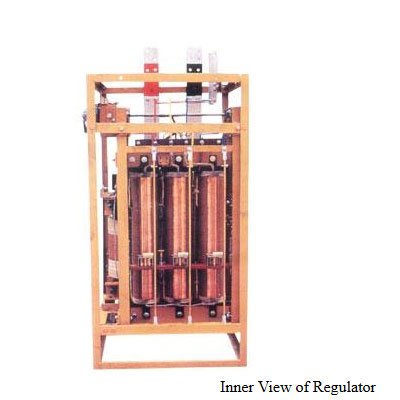

DC Output Control

The function of the variable output controls is to control the voltage or current or its operating range by varying input voltage to the main transformer primary. The DC output voltage variation is achieved steplessly 0-100% by means of an ON LOAD roller type Jindal's make voltage regulator.

Salient Feature

- We use verticle Rolling contact type voltage regulator wound with heavy section of copper strips suitable for 100% continuous duty cycle for industrial applications, in comparison to conventional wire wound Regulators used by other manufacturers. The carbon rollers move on both sides of the winding.

- DIODE : Silicon diodes are tested in house, similar PIV batch and same forward drop diodes are used in the equipment for equal load sharing and reducing the power losses of diodes.

- LAMINATION CORE : We use imported CRGO Lamination core which have minimum power losses and results in better efficiency of equipment and saving in energy bill.

- PAINTS : Epoxy paint is used which is resistant to acidic environment of plating process and enhance the life of the equipment by preventing it from corrosion.

- METER : We use reputed make AE/RISHAB make DC meters only which are very accurate and durable. CONSTANT VOLTAGE CONTROLLER (CVC) (OPTIONAL) : We offer CVC Electronic attachment with rectifier equipments, which will maintain constant Output Voltage or Current as per setting automatically-irrespective of input voltage variation.

Guarantee

Our Equipments are Guaranteed for 5 Years against any Manufacturing Defect.

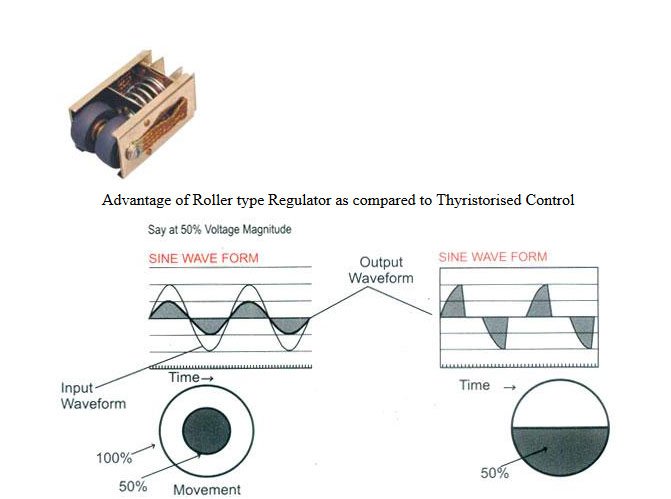

WHY THE REGULATOR CONTROL IS SUPERIOR TO THYRISTORISED CONTROL IN RECTIFIER

In plating application the regulator is better and technology is adopted in Germany and Europe because of as explained above in point 1 to 5. Other manufacturer of rectifiers have shifted to thyristors because they have to use sliding carbon brush type regulators. Manufacturers of rectifiers claim that thyristor controlled rectifiers has been losses than regulator. They compare thyristor with sliding carbon type regulator. In our case their claim is not true. We use vertical coil type rolling carbon regulator. The copper section is three times so the losses are almost 1/6 or 20%.

| Roller Type Regulator | Thyristorised Control |

| 1.No wave form distortion at any load. Electrical wave form is like a moving wheel. For 50% Rated Voltage the Dia of wheel is reduced accordingly i.e. magnitude for a wave is decreased. | 1.Wave form distortion. It is like cutting the wheel by 50% and then moving the wheel i.e. wave form is cut as shown at full magnitude. |

| 2.Higher power factor of more than 0.95 is achieved. | 2.The power factor is lower between 0.5 to 0.9 |

| 3.The system is simple and can be repaired and maintained even by simple mechanic. | 3.The system is specified and needs specially trained Electronic Engineer to repair and maintain. |

| 4. The cost of spares is very negligible. | 4. The cost of replacement is very high. |

| 5. Over all losses are less. | 5. Over all losses are more |

WHY THE REGULATOR CONTROL IS SUPERIOR TO THYRISTORISED CONTROL IN RECTIFIER

In plating application the regulator is better and technology is adopted in Germany and Europe because of as explained above in point 1 to 5. Other manufacturer of rectifiers have shifted to thyristors because they have to use sliding carbon brush type regulators. Manufacturers of rectifiers claim that thyristor controlled rectifiers has been losses than regulator. They compare thyristor with sliding carbon type regulator. In our case their claim is not true. We use vertical coil type rolling carbon regulator. The copper section is three times so the losses are almost 1/6 or 20%.

CUSTOMER CARE

If you have an emergency need, simply call our 24 x7 hour helpline

Copyright © 2024 All Rights Reserved.